Page 123 - RACI

P. 123

MOUNtINg 13

Hdpe spacers

asseMBly instructiOns

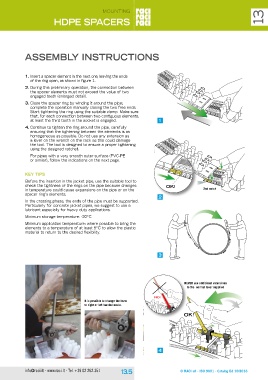

1. Insert a spacer element in the next one, leaving the ends 1 2nd notch

of the ring open, as shown in figure 1.

OK!

2. During this preliminary operation, the connection between 2

the spacer elements must not exceed the value of two

engaged teeth (enlarged detail).

3. Close the spacer ring by winding it around the pipe;

complete the operation manually closing the two free ends.

start tightening the ring using the suitable clamp. Make sure

that, for each connection between two contiguous elements,

at least the third tooth in the socket is engaged.

4. Continue to tighten the ring around the pipe, carefully

ensuring that the tightening between the elements is as

homogeneous as possible. Do not use any extension as

a lever on the wrench on the rack as this could damage

the tool. the tool is designed to ensure a proper tightening

using the designed ratchet.

For pipes with a very smooth outer surface (PvC-Pe

or similar), follow the indications on the next page.

Key tips

Before the insertion in the jacket pipe, use the suitable tool to

check the tightness of the rings on the pipe because changes

in temperature could cause expansions on the pipe or on the

spacer ring’s elements.

In the crossing phase, the ends of the pipe must be supported.

Particularly for concrete jacket pipes, we suggest to use a

lubricant especially for heavy duty applications.

Minimum storage temperature: -20°C

Minimum application temperature: where possible to bring the

elements to a temperature of at least 5°C to allow the plastic

material to return to the desired flexibility.

3

NEVER use additional extensions

to the normal lever supplied

It is possible to change the lever NO!

to right or left handed mode.

OK!

info@raci.it - www.raci.it - Tel. +39 02 262.351 4

© RACI srl - ISO 9001 - Catalog ed 10/2016