SPECIAL FEATURES:

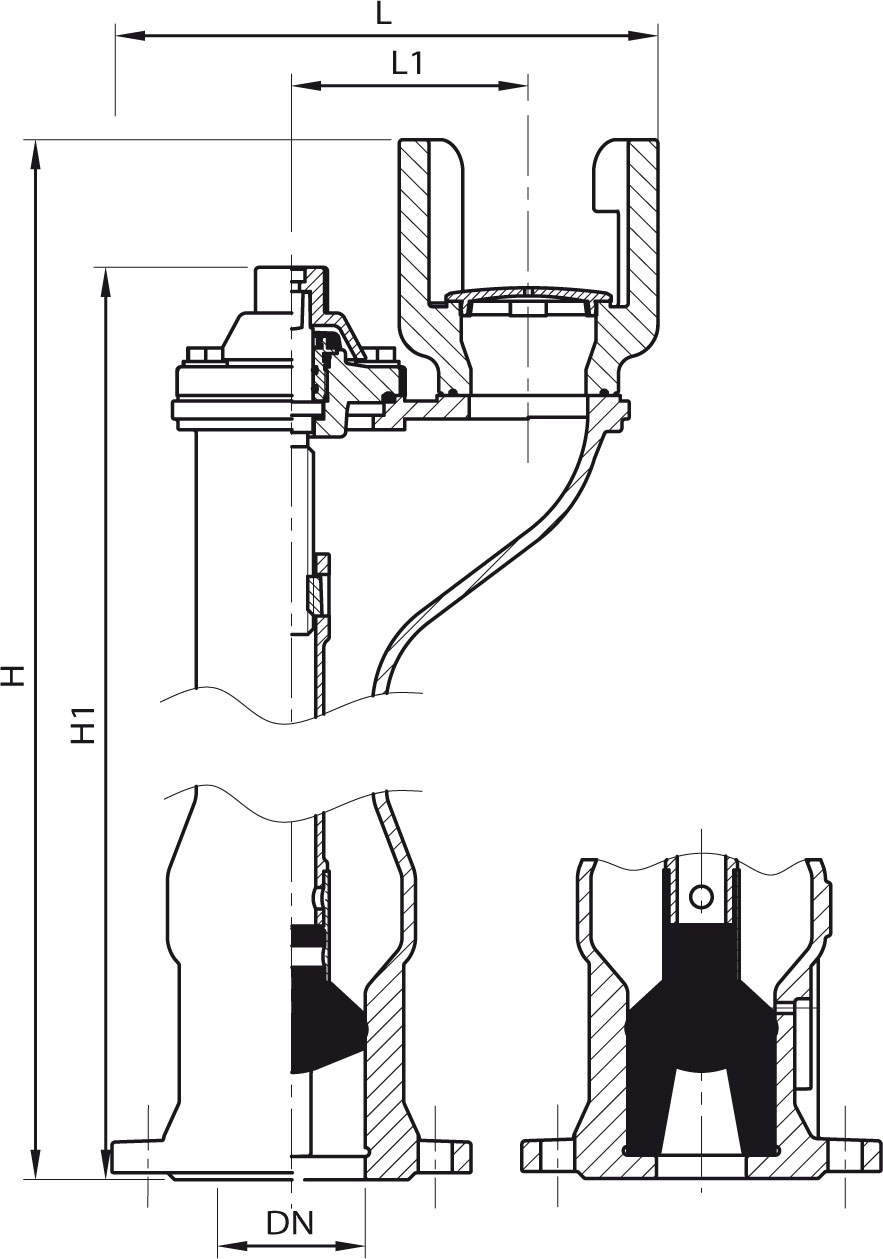

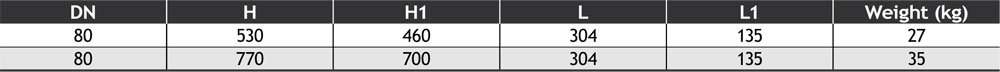

- Fire hydrant for underground installation, H1 type (short) and H2 type (long).

- According to the requirements of EN 14339 type B and EN 1074-6.

- Hydrant column and bonnet high quality EPOXY powder coated (fusion bonded), UV deterioration resistant.

- Special spider and body slide to guide stopper operation.

- Multiple O-ring spindle sealing system embedded in non-corrosive material to DIN 3547-1.

- Stainless steel spindle (single forged round bar with rolled threading).

- Gliding disc on the spindle neck to reduce friction when operating the spindle.

- Plug fully rubber vulcanised with special O-ring profile for soft lateral sealing without high compression of any rubber.

- Automatic drainage system at closed position of the plug.

- Outlet with bayonet coupling for quick engagement. Others on request.

- Possibility for mounting customized indicator plate (name, logo, etc.).

- CE CPR305/2011

MATERIALS:

Column and bonnet:

Ductile iron EN-GJS-400-15 / EN 1563 (former to DIN GGG40)

Spindle:

Stainless steel 1.4021/EN ISO 10088 (equivalent to UNI X20Cr13 or AISI420)

Plug:

Ductile iron EN-GJS-400-15 / EN 1563 fully EPDM rubber vulcanised, potable water approved

Bush and pipe nut:

Brass CuZn40Pb2

Operating pipes:

Steel C40 galvanized (on request stainless steel 1.4301 / EN ISO10088 - AISI304)

Friction disc:

POM resin

O-Rings and gaskets:

EPDM rubber, potable water approved

Operating cap:

Aluminium (brass on request)

Bolts/nuts/washers:

Stainless steel A2-70 / EN ISO 3506

OPERATION:

Manual action by pentagonal key as standard

All metal, rubber, and coatings used have been designed for contact with water for human consumption, pursuant to the terms of Italian Health Ministry decree n° 174, dated 6/4/2004.

HYDRANTS UNDERGROUND TYPE “VIRGILIO”

HYDRANTS UNDERGROUND TYPE “VIRGILIO”