SPECIAL FEATURES:

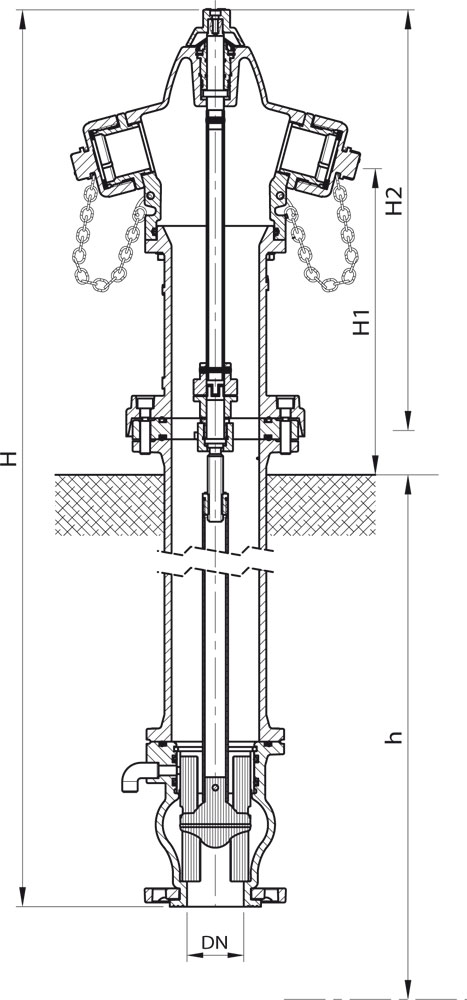

- Proper screwed connection between head and column with prearranged breaking section.

- The breakaway system to avoids the water losses in case of accidental break of hydrant by an impact with separation of hydrant head from its column.

- According to the requirements of EN 14384 type C and EN 1074-6.

- Generously oversized column for high water capacity.

- Plug fully rubber vulcanised with special O-ring profile for soft lateral sealing without high compression of any rubber.

- Hydrant head, column and base high quality EPOXY powder coated (fusion bonded), UV deterioration resistant.

- Multiple O-ring spindle sealing system embedded in non-corrosive material to DIN 3547-1.

- Stainless steel spindle (single forged round bar with rolled threading).

- Gliding disc on the spindle neck to reduce friction when operating the spindle.

- Sealing seat from stainless steel cylinder replaceable deeply corrosion and lamination resistant.

- Automatic drainage system at closed position of the plug.

- Routable flange at hydrant inlet for easy positioning.

- Marking according to EN 19.

- Outlet couplings (hose connections) and operating caps according to various standards possible, according to the following combinations 2 x 2’ 1/2”; 2 x 2 1/2” + 1 x 4”

- Possibility for mounting customized indicator plate (name, logo, etc.).

- Suitable complete with 90° duckfoot bend.

- CE CPR305/2011

- Available protection helmet (MOD. 6200 pag. 6.5) realized in ABS resin, designed to cover the hydrant complete with outlets and covers.

MATERIALS:

Head, column, basement and fl anged connection:

Ductile iron EN-GJS-400-15 / EN 1563 (former to DIN GGG40)

Spindle:

Stainless steel 1.4021/EN ISO 10088 (equivalent to UNI X20Cr13 or AISI420)

Plug:

Ductile iron EN-GJS-400-15 / EN 1563 fully EPDM rubber vulcanised, potable water approved

Bush and pipe nut:

Brass CuZn40Pb2

Operating pipe:

Steel C40 galvanized (on request stainless steel 1.4301 / EN ISO10088 - AISI304)

Drive:

Ductile iron EN-GJS-400-15 / EN 1563 galvanized

Friction disc:

POM resin

O-Rings and gaskets:

EPDM rubber, potable water approved Operating cap, nipples and plugs: Aluminium (brass on request)

Chains:

Stainless steel 1.4301/EN ISO 10088 (AISI304)

Bolts/nuts/washers:

Stainless steel A2-70 / EN ISO 3506

OPERATION:

Manual action by pentagonal key as standard

All metal, rubber, and coatings used have been designed for contact with water for human consumption, pursuant to the terms of Italian Health Ministry decree n° 174, dated 6/4/2004.

HYDRANTS BREAK AWAY TYPE “OMERO”

HYDRANTS BREAK AWAY TYPE “OMERO”