SPECIAL FEATURES:

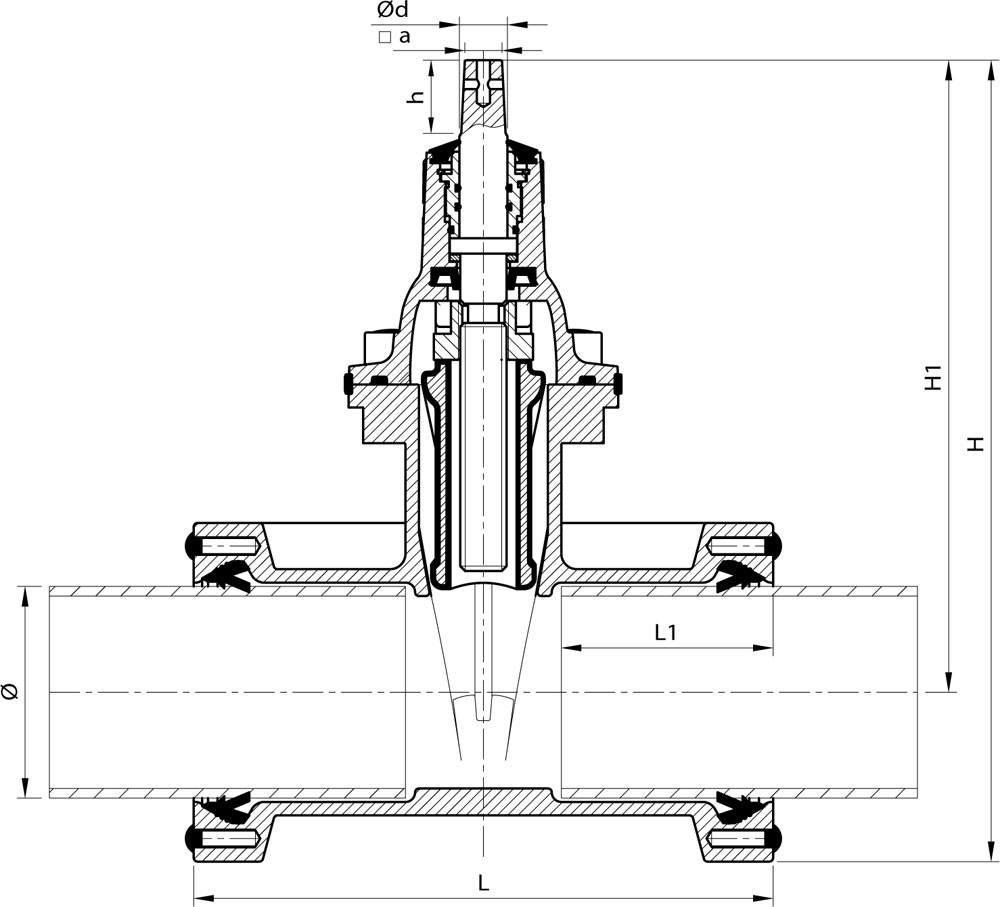

- Special gate valve to connect directly PVC pipes, connection sealing by double lip gasket.

- Perfect sealing on plastic pipe by back seal hydraulically operating. Special gasket KTW, W270 and EN 681-1 WA approved.

- Manufactured according to the requirements of EN 1074 and EN 1171 (min. torque strength Class2).

- Body and bonnet high quality EPOXY powder coated (fusion bonded), coating thickness DFT min. 250 micron, zero porosity (tested with 3000V), high impact resistance and cross-linkage according to DIN 30677-2 and DIN 3476.

- Multiple O-Ring spindle sealing system embedded in noncorrosive material to DIN 3547-1 and additional back lip-seal for double security.

- O-Rings changeable under pressure to ISO 7259.

- Non-rising stainless steel spindle (single forged round bar with rolled threading).

- Wedge inside and outside fully rubber vulcanised, with drain hole and special guiding rails to minimize friction.

- Solid flexible wedge nut from corrosion free material.

- Gliding disc on the spindle neck to reduce friction when operating the spindle.

- Bolts protected against corrosion by special resin.

- Protection ring between body and bonnet to reduce risk of damages on the coating due to mechanical impacts during transport, handling and installation.

- Markings following EN 19.

- Manual operation by handwheel, operating cap, extension spindle (underground installation).

MATERIALS:

Body and bonnet:

Ductile iron EN-GJS-400-15/EN 1563 (former to DIN GGG40)

Spindle:

Stainless steel 1.4021/EN ISO 10088 (equivalent to UNI X20Cr13 or AISI 420)

Wedge:

Ductile iron EN-GJS-400-15/EN 1563 (former to DIN GGG40), EPDM rubber vulcanised, potable water approved

Wedge nut:

Brass CuZn40Pb2

O-Ring bush:

Brass CuZn40Pb2

Gliding disc:

POM

O-Ring, back seal, bonnet seal and dust cap:

EPDM rubber, potable water approved

Bonnet allen screws:

Steel class 8.8 to EN ISO 898-1, corrosion protected by special seal

Protection ring:

Reinforced plastic material

I materiali costituenti il prodotto (i metalli, le gomme, le plastiche e i rivestimenti) sono stati selezionati con particolare attenzione agli aspetti igienico-sanitari. Prove di cessione e composizione presso laboratori indipendenti ne hanno attestato la conformità ai requisiti di legge per i prodotti a contatto con acqua potabile – D.M.174:2004.

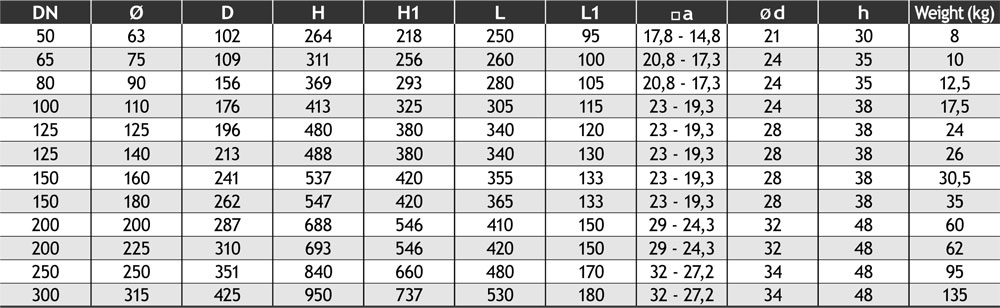

GATE VALVES SOCKET ENDS FOR PVC PIPES

GATE VALVES SOCKET ENDS FOR PVC PIPES