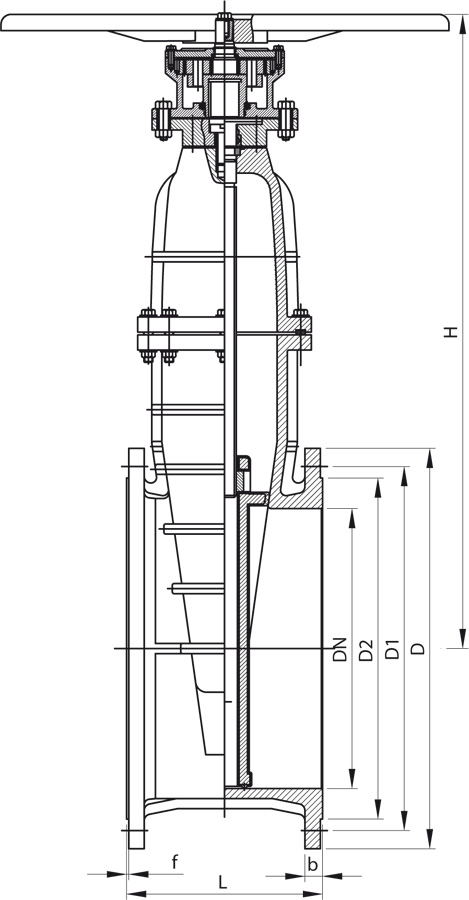

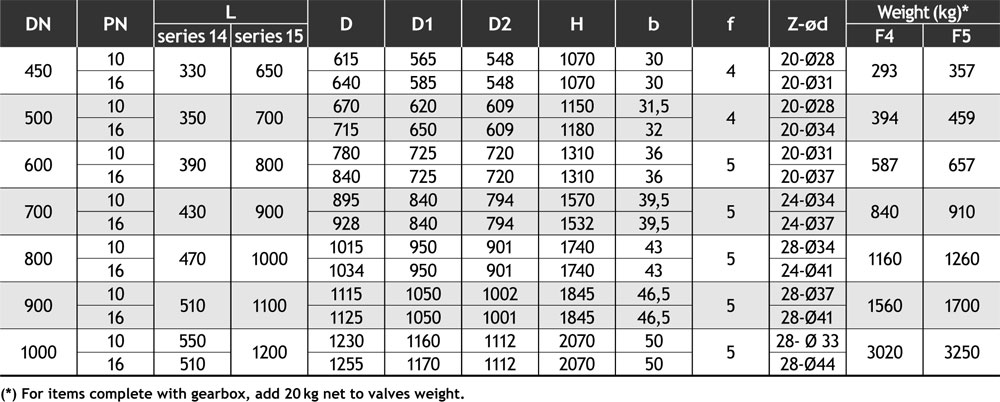

- Flange drilling and face-to-face dimensions according to eN 1092-2 and eN 558 (series 14 and series 15).

- Primary sealing obtained by compression of rubber wedge.

- Secondary sealing obtained by OR gaskets embedded in non-corrosive material.

- Internal and external epoxy coating (average thickness 250μm).

- Manual operation by hand wheel DN 450.

- DN 450-1000 operated directly by handwheel or gearbox (optional).

MATERIALS:

Body and bonnet:

Ductile iron EN-GJS-500-7/EN 1563 (equivalent to DINGGG50)

Stem:

Stainless steel 1.4021 (equivalent to AISI 420)

Wedge:

Ductile iron EN-GJS-500-7/EN 1563 (equivalent to DINGGG50), fully coated with EPDM gasket

Bolts and nuts:

Stainless steel A2

All metal, rubber, and coatings used have been designed for contact with water for human consumption, pursuant to the terms of Italian Health Ministry decree n° 174, dated 6/4/2004.

BIG SIZE GATE VALVES FLANGED ENDS

BIG SIZE GATE VALVES FLANGED ENDS