- Direct connection to the pipe saddles, suitable for under pressure drilling.

- Manufactured according to the requirements of EN 1074.

- Body and bonnet high quality powder coated (fusion bonded), coating thickness DFT min. 250 micron, zero porosity (tested with 3000V), high impact resistance and

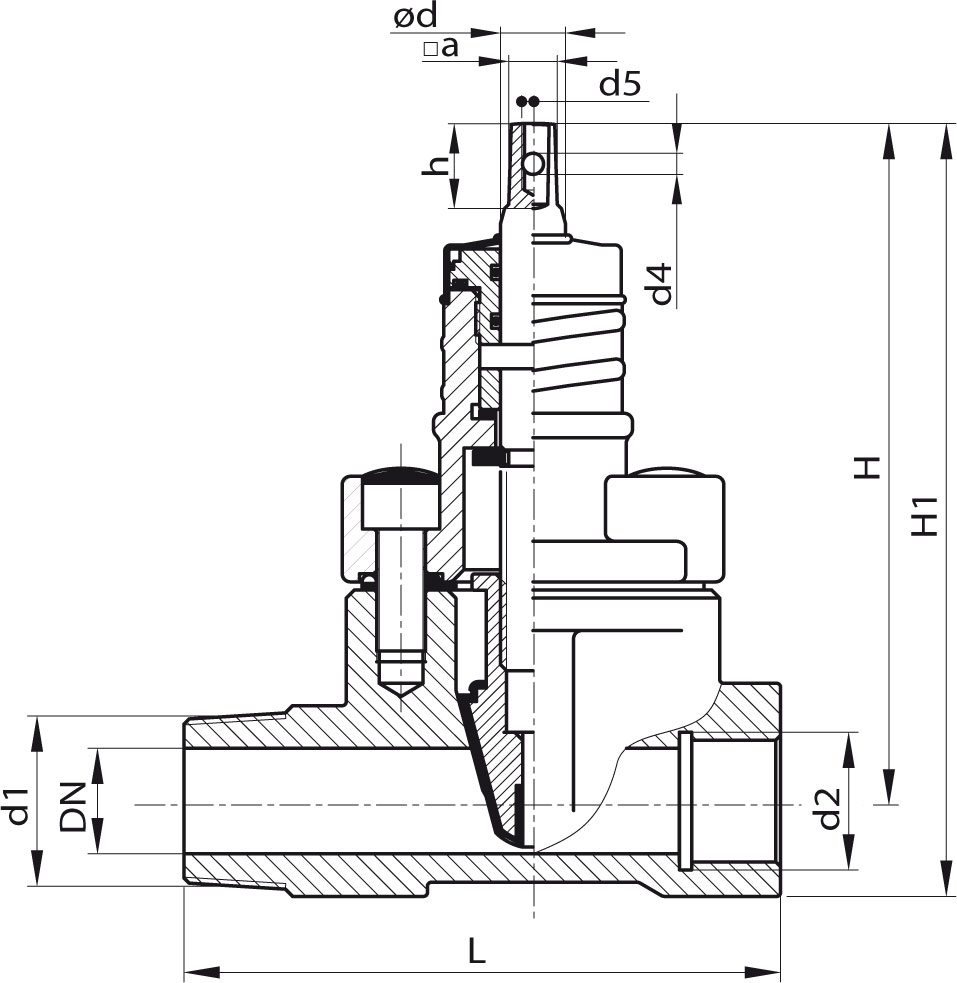

cross-linkage according to DIN 30677-2 and DIN 3476. - Multiple O-Ring spindle sealing system embedded in noncorrosive material to DIN 3547-1.

- Additional back sealing disc for O-Rings replacement under pressure to ISO 7259.

- Anti friction bush on spindle neck.

- Non-rising stainless steel spindle (single forged round bar with rolled threading).

- Wedge on sealing surfaces completely rubber vulcanised, with drain hole.

- Threads according to EN 10226 -1.

- Fasteners protected against corrosion by special resin sealing.

- Manual operation by handwheel, operating cap, extension spindle (underground installation).

MATERIALS:

Body and bonnet:

Ductile iron according to EN-GJS-400-15 /EN 1563 (former to DIN GGG40)

Spindle:

Stainless steel 1.4021/EN ISO 10088 (equivalent to UNI X20Cr13 or AISI420)

Wedge:

Brass CuZn40Pb2, rubber vulcanised, potable water approved

O-Ring bush:

Brass CuZn40Pb2

Anti-friction bush:

POM

O-Rings, back seal, bonnet seal and dust cap:

Rubber, potable water approved

Fastening screws:

Stainless steel A2-70/EN ISO 3506

All metal, rubber, and coatings used have been designed for contact with water for human consumption, pursuant to the terms of Italian Health Ministry decree n° 174, dated 6/4/2004.

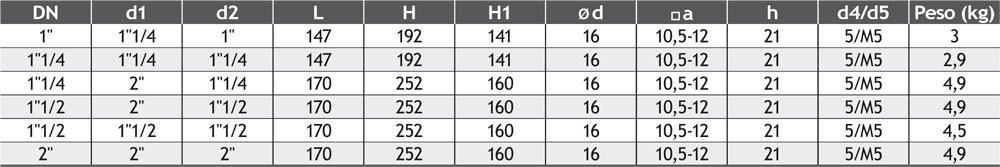

SERVICE VALVES MALE / FEMALE

SERVICE VALVES MALE / FEMALE