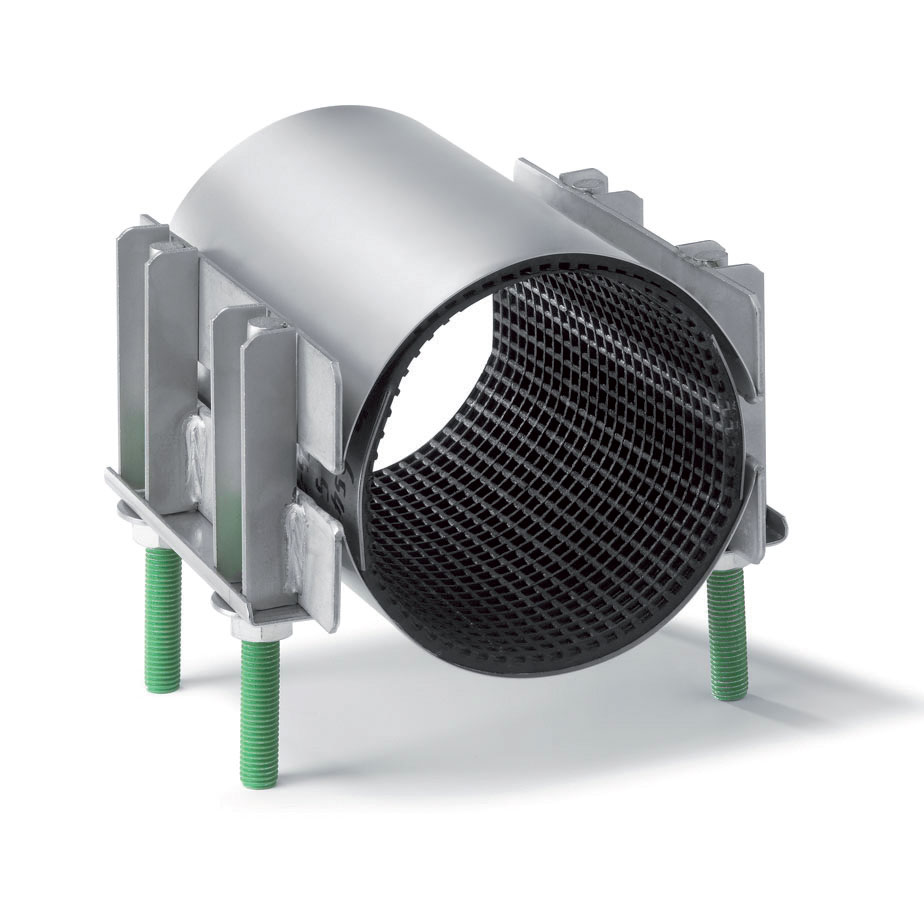

SPECIAL FEATURES:

- Sealing and repairing of cracks, holes and breaks on pipes, even for oval pipes, pipes made from different materials (steel, ductile iron, asbestos cement, plastic) carrying water and other fluids in pressure or not.

- Connection of off centre pipes (max. angular flexion of 2°) and pipes are out of line or offish (few millimetres of distance).

- Wide tolerance on the external diameter of the pipe.

- Light and easy to install.

- Made by two work pieces. Repair clamps can be obtained by connecting more terminal junctions.

- Rapid socket bolt each 100 mm length, Teflon coated in threaded part to avoid gripping problems.

- Fully realized from stainless steel with passivated welding for an high resistance to corrosion.

- Voltaic cell effect by using different materials (i.e. ductile iron terminal junction + stainless steel band+ steel bolts) is avoided.

- The terminal junction is welded on the band allowing an increasing of tightening torque for each bolt ensuring a better sealing of the clamp.

- Available with flanged outlet (series 30) from DN 50 up to DN 200 and PN 10 or 16 drilling. Band range from 10 mm (standard) up to 20 mm (on request).

- Available with outlet with parallel internal threading Rp ½” – Rp 3”.

MATERIALS:

Band and clamp:

Stainless steel 1.4301 (equivalent to AISI 304) on request 1.4401 (equivalent to AISI 316)

Sealing gasket:

Rubber with grid profile

Rods:

Stainless steel 1.4301 (equivalent to AISI 304) with Teflon coating on threaded part

Nuts:

Stainless steel A2-70 EN ISO 3506

All metal, rubber, and coatings used have been designed for contact with water for human consumption, pursuant to the terms of Italian Health Ministry decree n° 174, dated 6/4/2004.

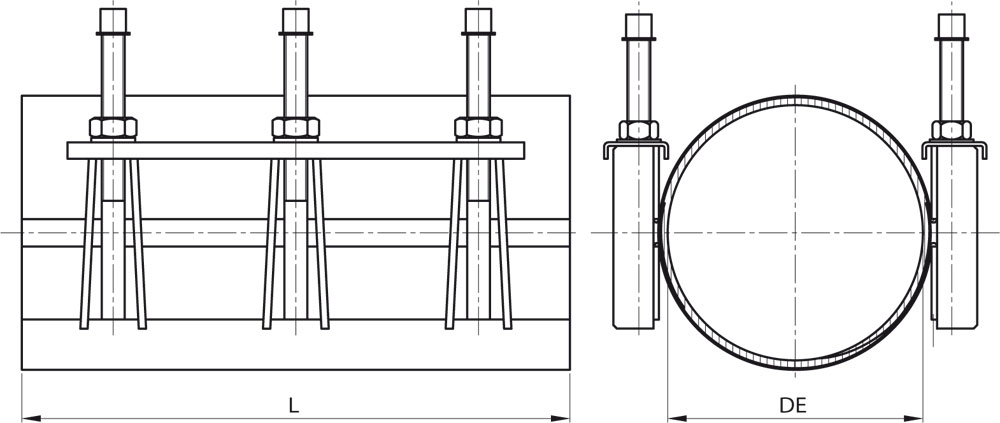

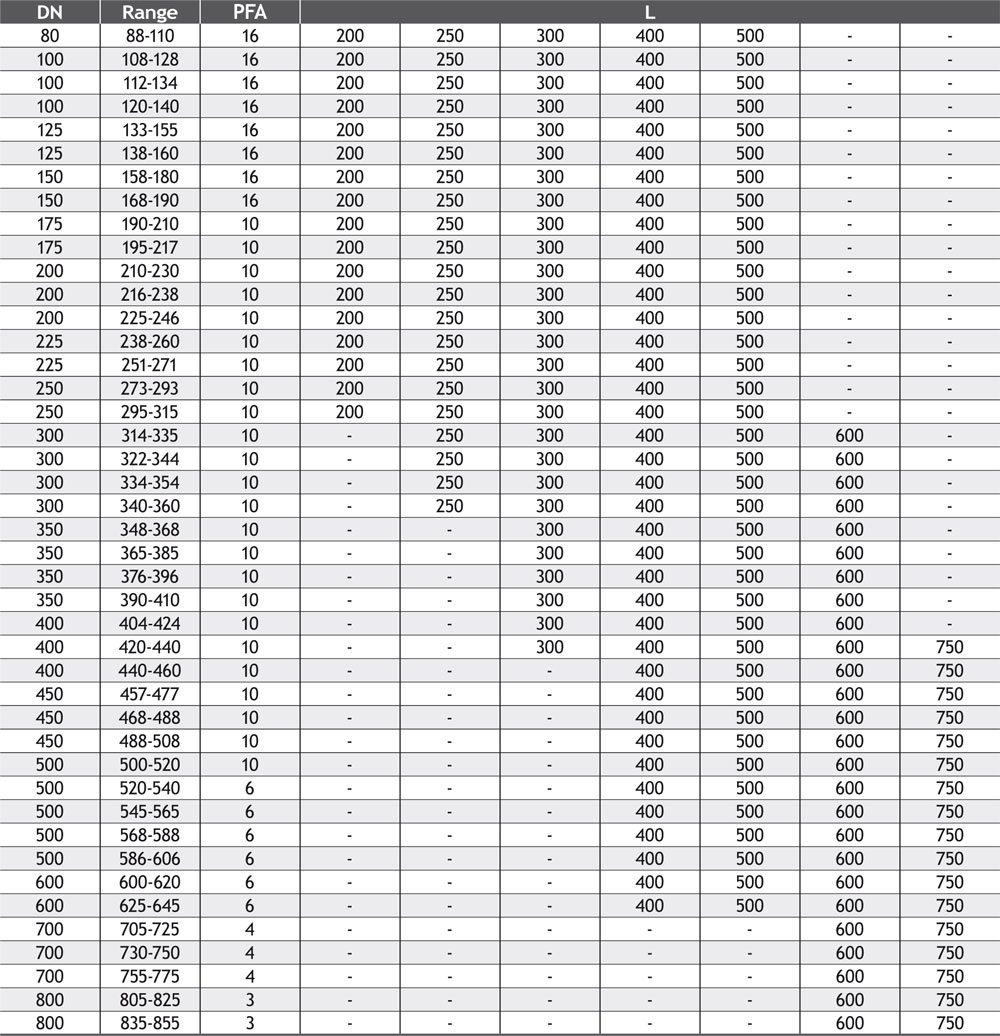

REPAIR CLAMPS SERIES 87X

REPAIR CLAMPS SERIES 87X