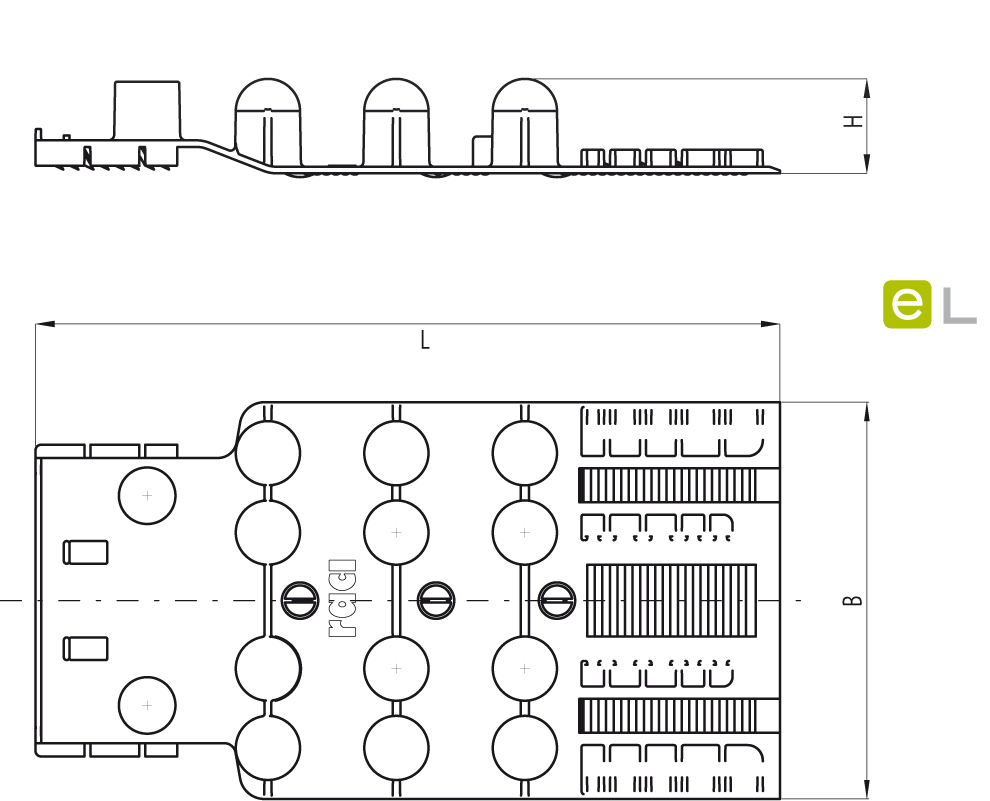

- Modular system to assemble insulator rings, which allows spacers to be used on a wide pipe diameter range therefore reducing inventory costs.

- Spacers are quickly and easily assembled by manually fitting elements one into the other.

- The tooth insertion method allows on site adjustments to fit a wide range of pipe diameters.

- Spacers are manufactured entirely out of high density polyethylene (HDPe). No metal bolts or attachments are required.

- A low friction coefficient guarantees an easy insertion into the casing.

- New design with special reinforcing ribs to guarantee high mechanical performances even with reduced thickness.

- Designed and tested to maintain continuous and long term support for the carrier pipe and its contents.

- Spacers provide a constant projection around the entire circumference of the carrier pipe.

- Spacers provide long term protection from corrosion.

- Spacers can be installed on steel-coated pipes, concrete pipes, ductile iron pipes or plastic pipes.

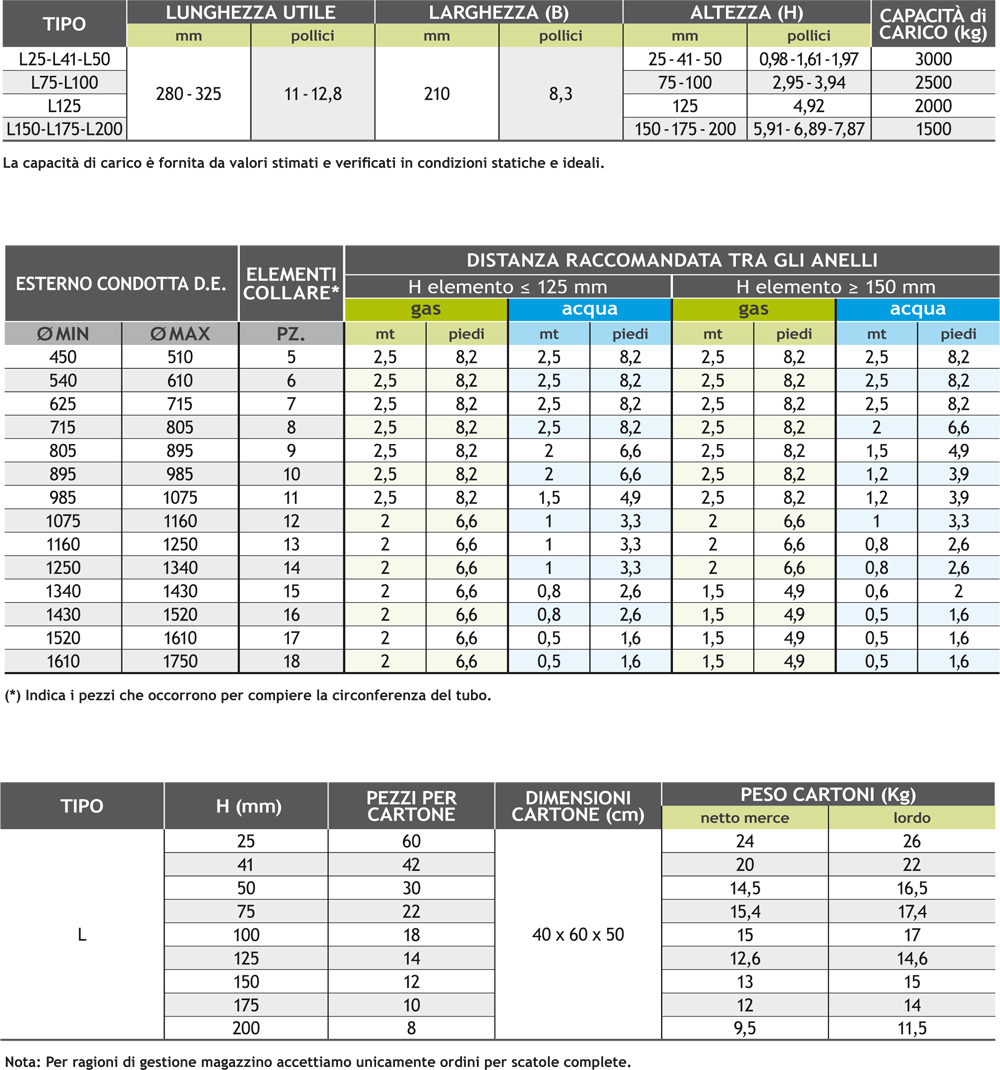

- Heights 25 mm and 41 mm homologated according to SNAM Rete gas specifi cation (GASD a 09.01.06 and GASD C 09.06.00).

- Tightening by tool type a75 for height up to 75 mm, tool type a200 for height from 100 up to 200mm.

MATERIAL - HDPE:

Yield strength*:

≥ 25 N/mm2 (test according to UNI eN IsO 527-2)

Elongation at break*:

> 200% (test according to UNI eN IsO 527-2)

Hardness shore D:

64 - astM D 2240

Minimum working temperature:

- 20°C (for applications below 5°C contact Raci)

Minimum stocking temperature:

- 5°C (for applications below 5°C contact Raci)

Dielectric strength:

> 37 kv/mm - astM D 149/64

UVL stabilization:

Good

(*) on test specimen with moulded material, realized and tested for every batch of production. Batch number is marked on each element recording nr/year of moulding.

HDPE SPACERS TYPE L

HDPE SPACERS TYPE L