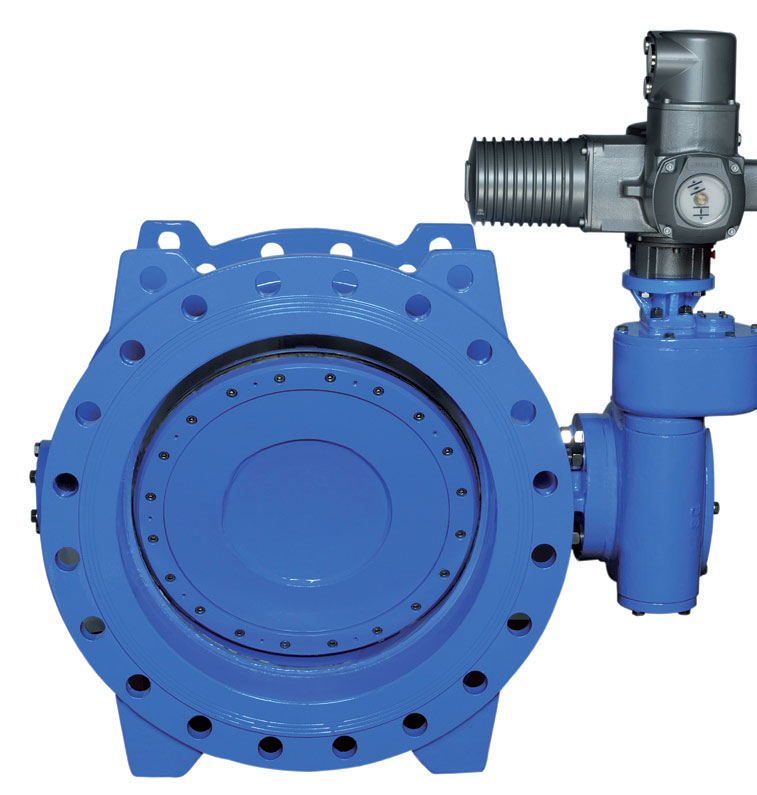

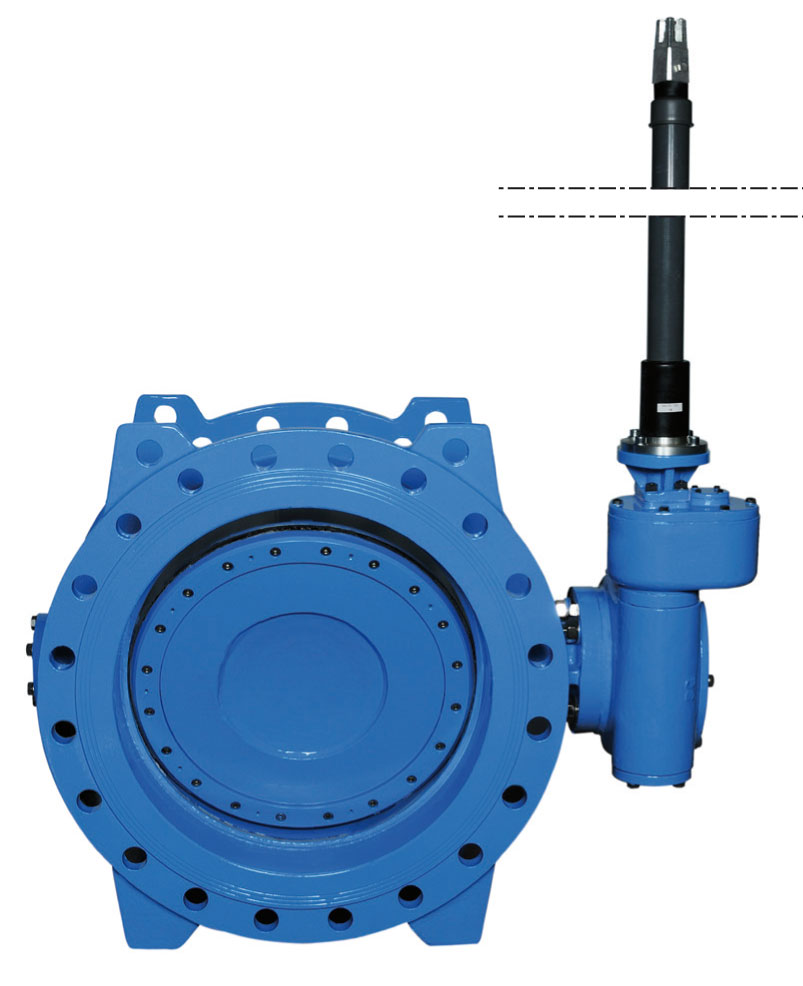

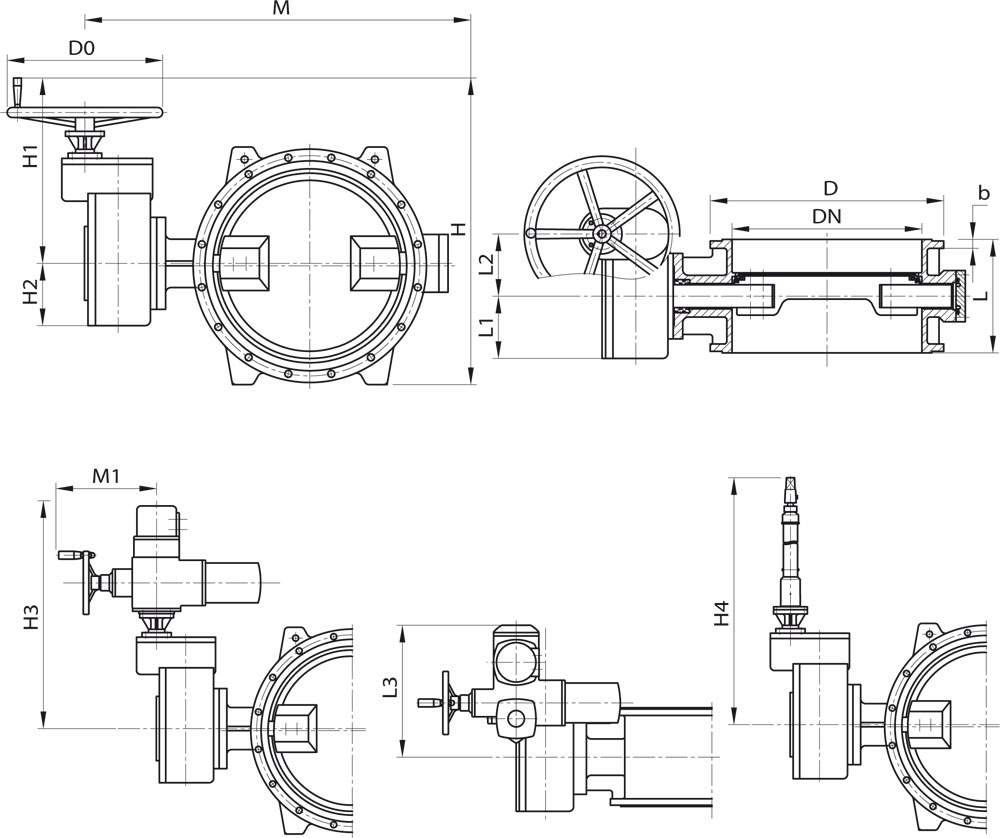

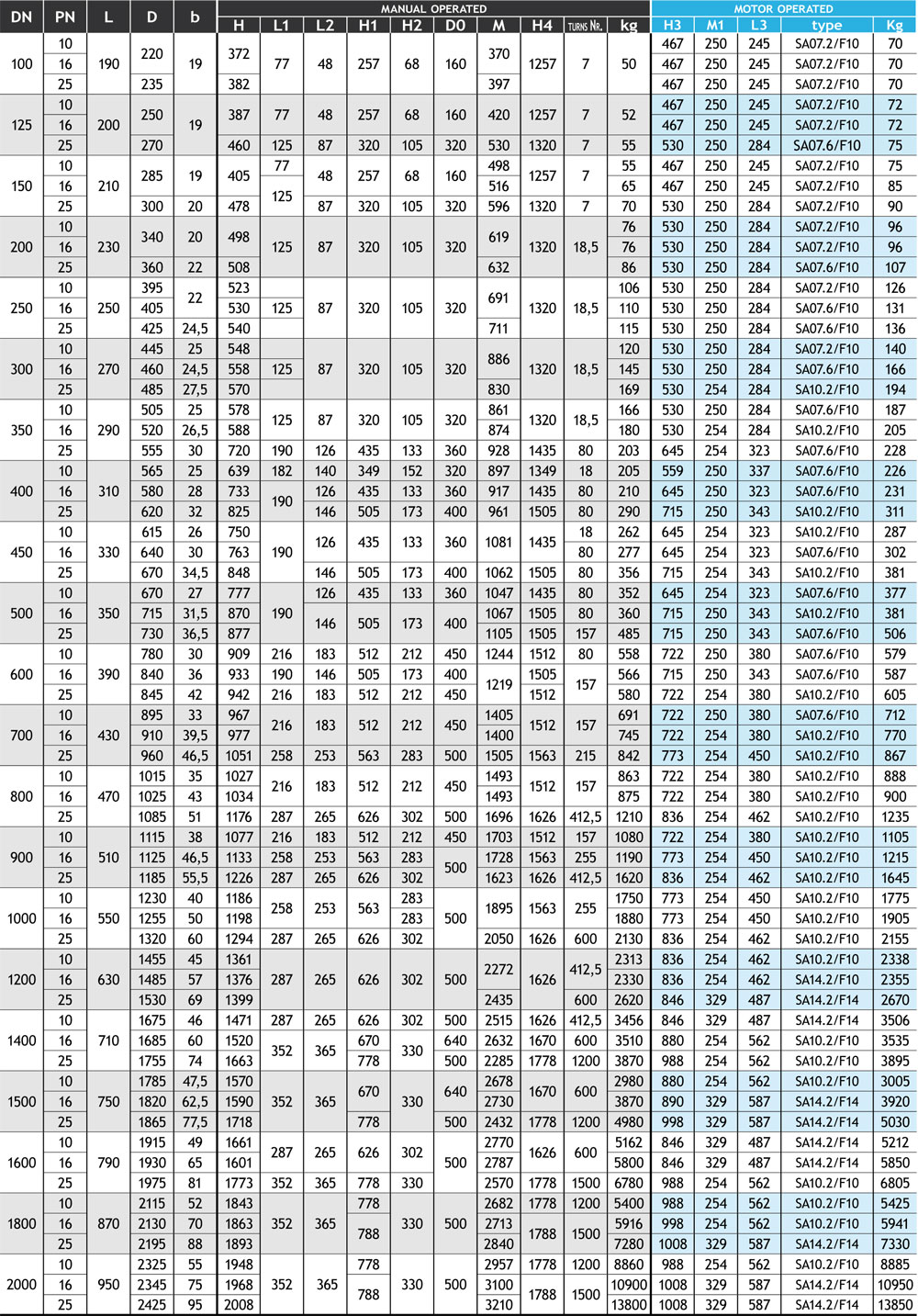

- Double eccentric type.

- Bidirectional sealing.

- Design according to the requirements of EN 1074.

- Face-to-face dimensions according to EN 558-1 Series 14 (former DIN 3202-F4).

- Body, disc, retainer ring and gear box high quality epoxy powder coated (fusion bonded) minimum thickness 250 microns.

- Sealing seat from CrNi hardened stainless steel, welded to the body and machined (or mechanical fixed, removable).

- Sealing gasket changeable.

- Shaft from stainless steel with maintenance-free O-ring sealing embedded in non-corrosive material to DIN 3547-1.

- Gear box flanges for mounting automatic electric actuators to EN ISO 5211.

- Manual operation by handwheel, operating cap, extension spindle (underground installation) or electrical actuator.

MATERIALS:

Body, disc, retainer ring and gear box:

Ductile iron EN-GJS-500-7/EN 1563 (former to DIN GGG50)

Shaft:

Stainless steel 1.4021/EN ISO 10088 (equivalent to UNI X20Cr13 or AISI420)

Sealing seat:

Austenitic nickel-chromium stainless steel (equivalent quality to AISI304)

O-Ring bush:

Brass CuZn40Pb2

Anti friction bushes:

Multilayer steel honeycomb and lubricating graphite

O-Rings and disc seal:

Rubber, potable water approved

All metal, rubber, and coatings used have been designed for contact with water for human consumption, pursuant to the terms of Italian Health Ministry decree n° 174, dated 6/4/2004.

BUTTERFLY VALVES DOUBLE ECCENTRIC TYPE

BUTTERFLY VALVES DOUBLE ECCENTRIC TYPE