SPECIAL FEATURES:

- Double orifice type, fully automatic triple function for releasing air during pipe filling and bringing air in (anti-vacuum) during pipe emptying, releasing air under pressure.

- Performances according to the requirements of EN 1074.

- Body and cover high quality polyamide (Rilsan – PA11) powder coated (fusion bonded), coating thickness DFT min. 250 micron, zero porosity (tested with 3000V), high impact resistance and cross-linkage according to DIN 30677-2 and DIN 3476.

- Floats from non-corrosive material.

- Body provided with threaded drilling for discharging ball valve connection (available on request).

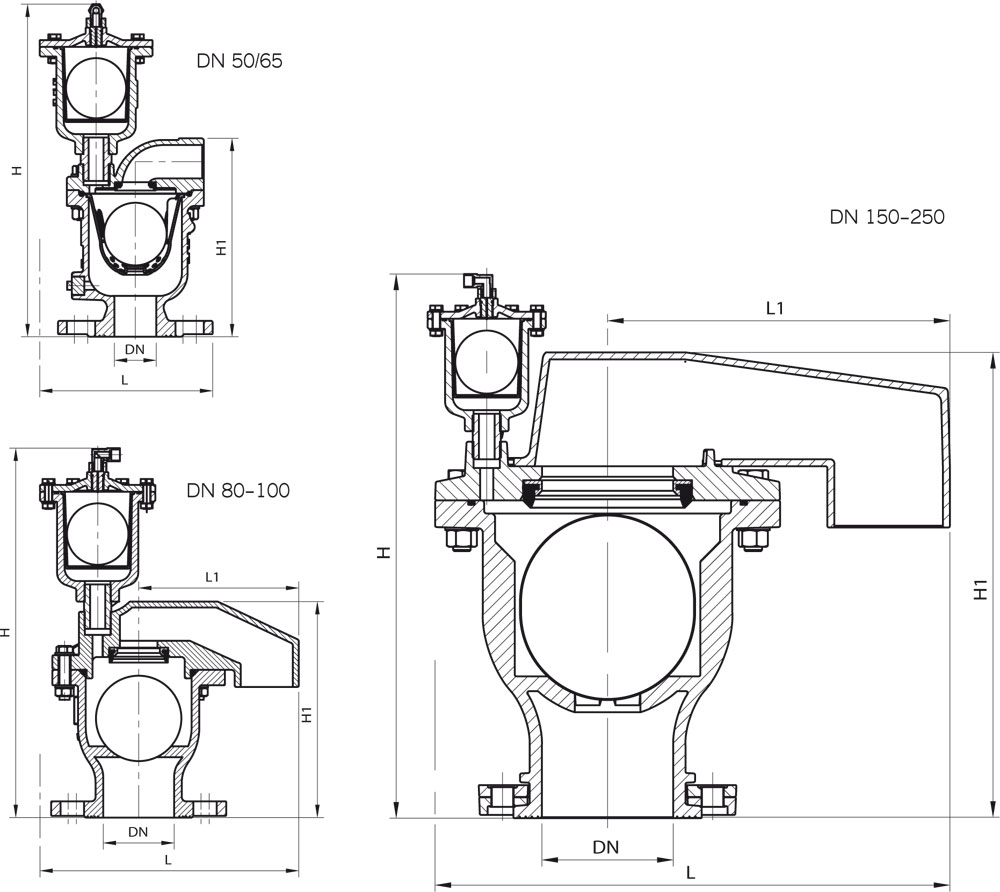

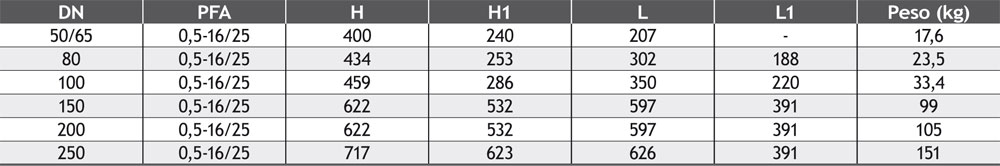

- Flanged connection with multi-size universal drilling to reduce stock variances (DN 50-65 PN 16-25; DN 80 PN 16-25 and DN 100 PN 16-25).

- From DN150 slip-on flange version: versatility and orientation changing on field option.

- Inner basket (up to DN80) or special guides into body casting (from DN150) to keep float in optimal position during operation.

- Minimum operating pressure for watertight: 0,5 bar.

>> PERFORMANCES:

FUNCTIONAL DIAGRAMS

MATERIALS:

Body and cover:

Ductile iron EN-GJS-400-15 / EN 1563 (former to DIN GGG40)

Kinetic unit float:

Up to DN80: polyamide, fully EPDM rubber lined PN10/16 or stainless steel 1.4301/ EN ISO10088 (equivalent to AISI304), fully rubber lined (DN 50/65) - PN 25

From DN100: stainless steel 1.4301 / EN ISO10088 (equivalent to AISI304)

Air release unit float:

Polyamide, fully EPDM rubber lined - PN 10/16

Stainless steel 1.4301/ EN ISO10088 (equivalent to AISI304), fully rubber lined - PN 25

Seat:

Brass CuZn40Pb2

Seat sealing:

Outlined EPDM rubber, potable water approved

Basket:

ABS

O-Rings:

EPDM rubber, potable water approved

Bolts/nuts/washers:

Stainless steel A2-70 / EN ISO 3506.

Stainless steel A4-70 on request

Plug:

Galvanised malleable iron, or stainless steel

All metal, rubber, and coatings used have been designed for contact with water for human consumption, pursuant to the terms of Italian Health Ministry decree n° 174, dated 6/4/2004.

AIR VALVES COMBINATI ON TYPE FROM DUCTILE IRON

AIR VALVES COMBINATI ON TYPE FROM DUCTILE IRON